Hi everyone,

We just became aware that Foolproof is closed tomorrow. As a result, we will be pushing our meeting back one week to the 16th.

If there are any further changes, we will update this post.

Best,

–Patrick

Hi everyone,

We just became aware that Foolproof is closed tomorrow. As a result, we will be pushing our meeting back one week to the 16th.

If there are any further changes, we will update this post.

Best,

–Patrick

Last month’s general meeting featured a fascinating presentation by our Social Media Officer, Charles Meyer, all about mead! He covered its rich history, diverse styles, helpful brewing tips, and essential tools. If you missed it, or want a refresher, you can find the slideshow here: Mead: Earth’s Oldest and Simplest Alcohol. Enjoy!

Hearing this usually irks me. It’s almost always said by someone who isn’t into craft beer who thinks beer and Bud should be synonyms. In my experience, they follow up with snark about “beer snobs” and the cost of a craft beer versus a cheap macro lager.

But in the age of juicy NEIPAs, s’mores-flavored stouts with lactose, and experimental beers with bacon and you name it, even those of us in the hobby sometimes want to taste a simple, clean beer without gimmicks. Just a refreshing lager… a “beer that tastes like beer.” Because I have no doubt, that when you think about that description without the negative connotations mentioned earlier, you probably think of a tall, cool glass of a clear yellow beer that is simple, clean, and refreshing. For me, I think of my senior year in college playing MLB The Show at my buddy’s apartment knocking back clear bottles of Miller High Life. And I still love that beer. Sometimes I just want a beer that tastes like beer.

So I wrote up this grain bill and offer it up to you guys to do with it as you will. I brewed this back in 2021 with friend and RIBS longtimer Ryan Durgin (who admittedly did all the real work). We fermented really low (49 degrees Fahrenheit) and admittedly had difficulties seeing any action so we bumped it up to 54 and she was off! We started at 1.039 and ended at 1.004 for a nice 4.59% Czech Pale Lager. My only regret is we split a 5 gallon batch instead of doing a 10 gallon batch. It was gone too soon.

Beer Without a Name

Style: Czech Pale Lager

Brewer: Patrick Canary & Ryan Durgin

5 lbs 8oz Pilsner

12oz Biscuit Malt

8oz Cara-Pils/Dextrine

4oz Acidulated Malt

1oz Sterling Hops @ 60 minutes

1 Package W-34/70

Ferment at ~53 Farenheit and for final 2 days, bump up to ~65-68 for diacetyl rest.

I’m taking to writing this blog post after the inspiration of conversations from a monthly RIBS meeting. My goal here is to highlight what I am working on, struggling with, successes and failures in order to hear from those with more experience in response, and maybe help those in a similar situation.

For the past year I have brewed, pretty much, the same NEIPA recipe. Typically, each batch I will change one or two things and make notes into Beersmith. My goal is to refine my recipes and my process. One focus has been on my kegging process. When experimenting with hopping rates, timing, etc. the common obstacle for me is clogged ball lock connectors. The amount of dry hops put into a NEIPA consistently clog up my connectors. I have tried increasing cold crash from 24 hours to 48. This helped slightly but didn’t totally fix the situation. My next solution was to keep multiple connectors on hand. Once one would get clogged I would attach another, purge out the air introduced to the line, and continue to transfer.

Unclogging and sanitizing and putting the connectors back into the rotation has “worked” but is very tedious, and frustrating. I’m also nervous about the opportunity for infection, introducing oxygen, and wasted beer (very minimal but still).

My next attempt is going to be to use an inline beer filter. My current plan is to purge the line of oxygen by letting beer flow through and sacrificing the first bit that comes out. My hope is that the micron filter won’t become too clogged in the process and I can transfer 5 gallons without having to clear out the filter.

If the filter does get clogged I will use the same process of cleaning, sanitizing, and purging the line of oxygen. I’m considering shortening the hose from the outlet to minimize the beer that would be lost.

In addition to trying to make the transfer process more streamlined, I have been changing my approach to carbonation as well. I know there are a few different camps out there on how this process should be done, i.e. set it and forget it vs. force carbonation. While I have had fine results with each method I have been transitioning to a slow and steady approach, with NEIPA batches at least. There are a couple reasons: it provides time for additional conditioning, and helps prevent over carbonation

The hype behind NEIPAs suggests that the closer to packaged date the better. This idea is that you are getting the absolute freshest beer possible. In my experience, this hasn’t ALWAYS translated to better beer. This notion was supported in Scott Janish’s The New IPA with an excerpt from New York’s Other Half Brewing in which they suggested their customers sit on their beer a week or two before drinking.

I have been concerned with over carbonation with my NEIPA batches. While it is an easy fix, releasing the excess CO2 will scrub out much of the aromatics from dry hop that I have strived to contain. This low and slow method has helped keep in the aroma from the dry hop while also giving the beer a little extra time to condition.

I’m interested in others that have taken a similar or even different approach. What have been your successes, failures,and solutions?

Here we go with another pro-wrestling themed beerski from yours truly, and this one actually won a major award, taking the bronze in the Specialty and Smoked (which apparently includes 34A – Clone Beers) category at the 2020 Dominion Cup. Seeing as it was the first Porter I’d done, I had to name it after one of the greatest United States Champions of all time, the one and only MVP. I also got what I can only interpret as his expressed certified endorsement via Instagram.

Now you all know I love me some ‘Gansett. This beer started life after I stumbled across a Charlie Papazian clone recipe of a Narragansett Porter that Falstaff brought to the GABF back in 1982. His review seemed positively wild to me, particularly the portion where he asserts that this could very well be America’s first dry-hopped beer. Seems like an outlandish statement, but hey, if it’s on the internet then it must be true.

I had to modify the recipe due to ingredient availability. Obviously Bullion hops are still very difficult to find, and I hadn’t yet harvested my first homegrown Cascade hop. I took the descriptors from Charlie’s writeup and found that Palisade (which I had on hand) could make a good replacement. I also didn’t have any black debittered malt, but I did have some Midnight Wheat which would help with the color while not adding too much bitterness. Finally, with Cry Havoc being retired (and me not being able to get Charlie’s Fist Bump that weekend) I went with WLP820 Octoberfest/Marzen Lager Yeast.

Yes, a lagered porter that isn’t Baltic.

It turned out delicious. It was light bodied, roasty, pleasantly hopped, and potentially one of the best beers I’ve ever made. Here’s the recipe.

Cheers!

Montel Vontavius Porter

5 gal batch

33.6 SRM

32.6 IBUs

Est OG 1.063

Est FG 1.012

ABV 6.69%

Grains

9lbs 8oz Marris Otter (3.0SRM

1lb Flaked Corn (1.3 SRM)

8oz Aromatic Malt (26.0 SRM)

8oz Midnight Wheat (744.27 SRM)

4oz Black Patent Malt (500 SRM)

Hops

3/4oz Hallertau – 60 mins

2oz Summit – 5 mins

1oz Cascade – Steep (see instructions below)

1oz Cryo Palisade – 7 days

Yeast

WLP820 Octoberfest/Marzen Lager

Add clarifying agent at 15 minutes left in the boil. Immediately chill to 190°F and add Palisade hops. Allow temperature to fall in ambient temperature (no chilling) to 180°F or 15 minutes, whichever comes first. Chill to 60°F and transfer to fermenter. Aerate well and pitch yeast, putting fermenter in fermentation chamber, use temp control to keep beer temp at 50°F until the gravity reaches 5 points off final gravity (probably 1-2 weeks), then raise temp to 65-70°F, dry hop, and continue to ferment for a week. Transfer to a secondary fermenter and lager, dropping temps to 38°F over the course of four weeks. Transfer to keg and force carbontate to 2.1. Vols CO2.

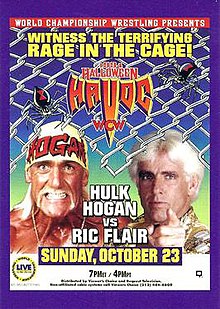

For those of you that are familiar with my brews, you’ve probably noticed that all of my beers are named with an old-school wrestling theme. Naturally when I thought to myself that it was high time I try and do an Oktoberfest that I should name it after the classic annual WCW pay-per-view “Halloween Havoc”. It’s currently lagering right now, so no idea how it tastes. I’m hoping the end product tastes like a Halloween Havoc 1993, but the process so far has been a real Halloween Havoc 1992.

First off, I have no temperature control, so an August ferment – even in my basement – was not going to yield a clean lager profile. So I thought outside of the box. I had heard that fermenting with Kviek yeasts at a cool 72 can yield lager-like qualities in a short time, so I settled on using Imperial Yeasts Loki and leaving the fermenter in my basement. Then life got in the way and every spare weekend I had was occupied by some household project, work responsibility, or (responsibly distanced) social commitment.

One of said household projects – unfortunately – was the eradication of a couple of mice that snuck in while we were having some work done on the house. I battled them for a couple of weeks but could never figure out where they were getting their food from. Then my wife noticed my grain bag (that had been sitting there for almost 3 months since I purchased all my ingredients) had started to spill a little bit. I’ll give you three guesses why.

Anyway, on what seemed like our last sunny October day, I finally got around to brewing a beer I’d been planning on since July. The Loki yeast worked well and acted on a more “normal” timeframe than you usually hear about these Kviek yeasts. I attribute that to the fermentation temperature between 67F and 70F. I popped it into the fridge to drop out the rest of the yeast and plan on kegging this weekend and letting it age for another couple of weeks. I’m not sure exactly what I’m expecting from it, but if it drinks anything close to a Marzen that means I’ll be able to drink one of my favorite beer styles year-round without expensive cooling technology.

Halloween Havoc

5 gal batch

8.9SRM

22 IBUs

Est OG 1.062

Est FG 1.012

ABV 6.4%

Grains

3lbs 8oz Munich Malt (9 SRM)

3lbs 8oz 2-Row (1 SRM)

3lbs 8oz Vienna Malt (3.5 SRM)

1lb Munich Malt (20 SRM)

8oz Caravienne Malt (22 SRM)

Hops

1/2oz Hallertau – 60 mins

1/2oz Tettnanger – 60 mins

1/2oz Hallertau – 15 mins

1/2oz Tettnager – 15 mins

Yeast

Imperial Labs Loki (Kviek)

Add clarifying agent at 15 minutes left in the boil. Immediately chill to 70°F. Pitch Loki and ferment between 65-70°F for two weeks. Transfer to secondary fermenter at lager temps for one week, then transfer to keg. Let age in keg for 2 weeks, carbonate, and enjoy.

We’ve got a new small-batch recipe submitted by Keith McAuslan. Happy brewing!

| Here is a brew that was inspired by a Magic the Gathering card. Many years ago my friend and I were in a long and drawn out game. we were getting down to the last cards in our decks. The cause of the issue was a single card he had out Gaea’s Liege. It turns all basic lands into forests. I wanted to honor that game with a beer. Felt it had to be woody but not piney or spruce tips. Maple, Oak etc… My friend has remarked about my first beers not having a head so it had to have a head also. This is the beer I designed. I had heard that Maple syrup in the boil can have a Woody taste. That is good for this concept. This is one of the top three beers I have made. Not sure I could even reproduce it again. It’s a concept beer,the taste of a forest glade, subtle but complex. |

Gaea’s grove

American Amber Ale (19 A)

Type: All Grain

Batch Size: 2.00 gal

Boil Size: 2.33 gal

Boil Time: 60 min

End of Boil Vol: 2.08 gal

Final Bottling Vol: 1.50 gal

Fermentation: Ale, Two Stage

Total Water Needed: 2.74 gal

Mash Ingredients

1 lbs 12.0 oz Pale Malt, 2-Row (Rahr) (1.8 SRM)

12.0 oz Wheat, Flaked (1.6 SRM)

8.0 oz Caramel/Crystal Malt – 20L (20.0 SRM)

5.6 oz Rye, Flaked (Briess) (4.6 SRM)

Mash In

Add 4.19 qt of water at 165.2 F 150.0 F 75 min

Fly sparge with 1.69 gal water at 168.0 F

Add water to achieve boil volume of 2.33 gal

Estimated pre-boil gravity is 1.032 SG

Boil Additions

0.25 oz Styrian Goldings [5.40 %] – Boil 60.0 min

4.0 oz Maple Syrup (35.0 SRM) Boil for 60 min

0.50 oz Northern Brewer [8.50 %] – Boil 10.0 min

8.0 oz Maple Syrup (35.0 SRM) Boil for 10 min

Estimated Post Boil Vol: 2.08 gal and Est Post Boil Gravity: 1.049 SG

Cool wort to fermentation temperature

Add water if needed to achieve final volume of 2.00 gal

Pitch Yeast and Measure Gravity and Volume

Fermentation and Ingredients

0.5 pkg Safale American (DCL/Fermentis #US-05)

4.0 oz Maple Syrup (35.0 SRM)

Original Gravity (Target: 1.049 SG)

Primary Fermentation (4.00 days at 67.0 F ending at 67.0 F)

Secondary Fermentation (10.00 days at 67.0 F ending at 67.0 F)

Final Gravity (Target: 1.003 SG)

Carbonation: Bottle with 1.18 oz Corn Sugar

Age beer for 30.00 days at 65.0 F

Our very own Scott had his Amber recipe sampled on the Brulosophy Podcast #151. Check out the recipe and the podcast below!

Nineteen Diggity-Two | Amber Ale

6 gallon batch

Grains:

Mecca Grade Pelton @ 49%,

Mecca Grade Lamonta @ 32%,

Briess c40 @ 4%,

Briess c80 @ 4%,

Mecca grade Vanora @ 6%

Briess Victory @ 2%,

Briess c120 @ 1%,

Briess chocolate malt @ 1.5%.

Hop Schedule:

Magnum – .33 oz @ 60min

Cascade – .50 oz @ 20 min

Centennial – .50 oz @ 20 min

Citra – .50 oz @ 10 min

Cascade – .50 @ 10 min

Centennial – 1 oz @ 2 min

Citra – 1 oz @ 2 min

– total of 35 IBU

Mash at 155F, Target 1.063 OG, 1.014 FG. 26.2 EBC for color.

Use a clean yeast. I prefer to warm ferment with imperial harvest @ 65F for 5 days, Bump to 70f for 2-3 days, cold crash to 33 for a day or so, keg and condition for 5-6 days, tap and drink. Gelatin fine if need be.

RIBS member (and teacher, if you can’t tell) Mike Gauthier presents a highly educational introduction to fermenting vegetables.

So I have always had an affinity for Belgian Trappist Beers. They always stood out to me with their unique flavors that set them apart from most of the beers on the commercial market. They interested me so much that they were among the first beers I ever started to brew and they make up about 90% of beers I brew now. I had brewed several Dubbels and Quadrupels with some great success, but for some reason, Belgian Tripel was a style I always had trouble nailing down. It wasn’t until I went to Belgium for my 30th birthday that I figured it out. The key element that I was lacking in my tripels were herbs and spices.

Now before you stop reading here and roll your eyes- this beer is not a Belgian wit, it’s not a BS pumpkin beer, it’s not a “spiced beer” of any kind. If you’re able to drink your beer and it tastes heavily of spices, you did it wrong. The key to making any Belgian style Trappist beer (in my opinion) is to have a deft hand with spices where they provide key background flavor notes without overtly taking over the beer.

Here’s my recipe for a Belgian Tripel which I developed after my trip to Belgium.

6 Gallon Recipe

8.5% ABV

78% Efficiency

OG: 1.077

OG: 1.013

Mash

14# Weyermann Pilsner Malt

1/2# Melanoidin Malt

Mash in at 151FMash out at 168F

Boil

1# Belgian Candi Sugar

1 oz Sterling hops (60 min)

1 oz Sterling hops (15 min)

11 grams crushed coriander seed (5 min)

1 star anise pod (5 min)

Fermentation

Imperial Monastic #B63 at 70F for 5 days, then allow it to free rise to 74F.

Pro tip: Dissolve the candi sugar in boiling wort in a separate pot before throwing it back into the main boil- you don’t want to scorch your sugar. Also, throw your crushed coriander and star anise pod into a mesh bag for easy removal after brew day.